Electricians wire new building

Our production process prioritises sustainability by minimising environmental impact. We use non-contaminating lubricants and follow strict cleaning procedures to protect the ecosystem while serving our customers.

We manufacture zinc rods using high-quality LME-approved zinc with a purity level of 99.995%, ensuring excellent conductivity and minimal impurities for reliable industrial performance.

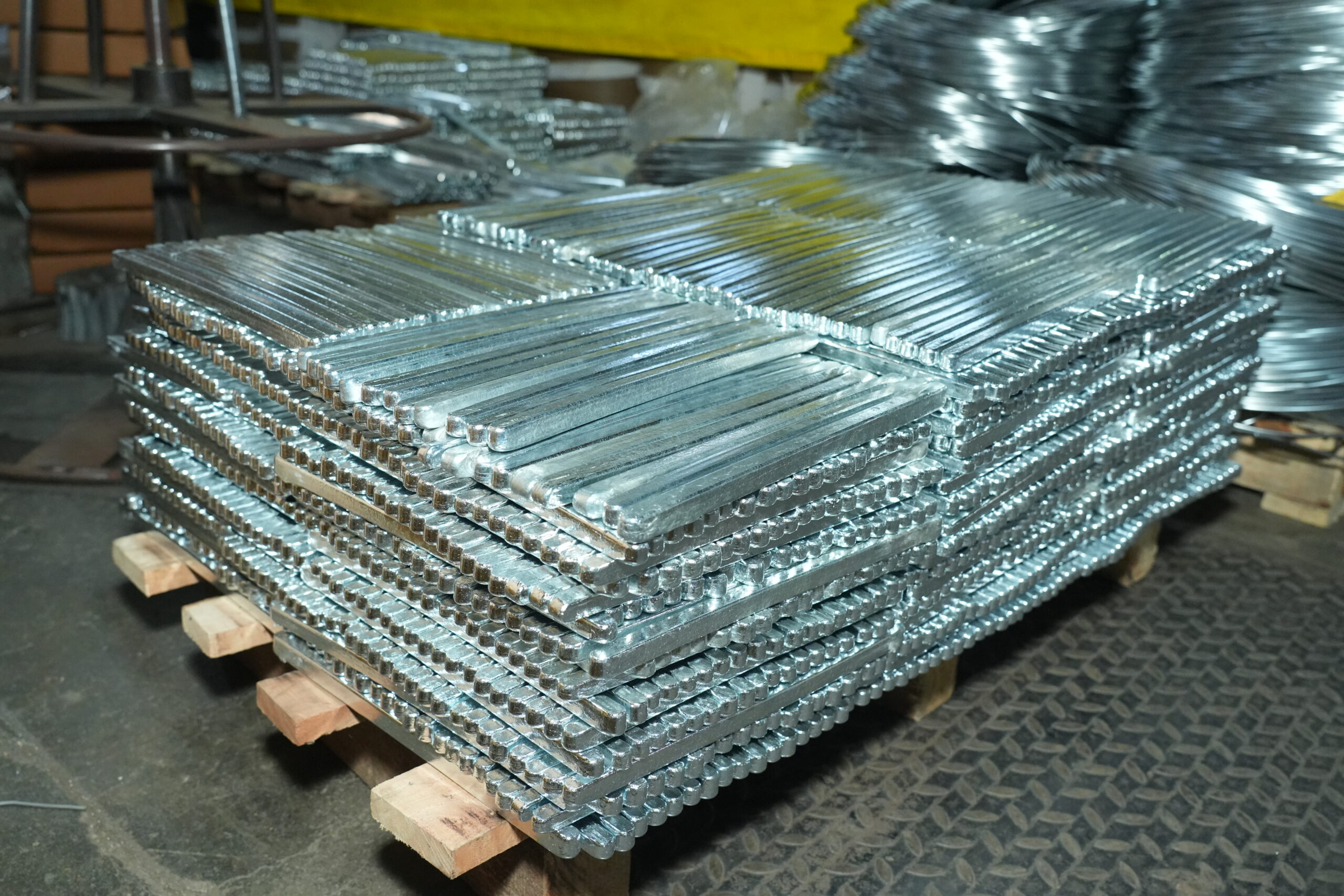

We manufacture a wide range of zinc rod sizes and offer customisation options to meet various industrial needs. Clients can choose specific dimensions, finishes and packaging for enhanced efficiency.

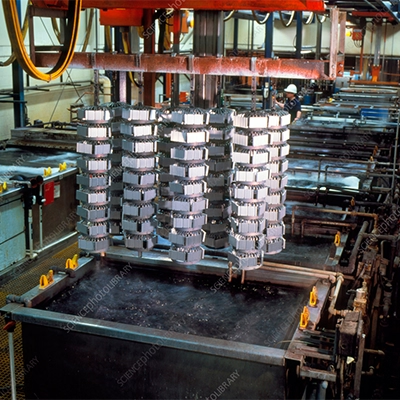

Zinc rods act as sacrificial anodes in the process of electroplating. When an electric current is applied, zinc oxidises instead of the substrate metal, enhancing the corrosion resistance of the plated object from moisture and corrosive agents while also adding a smooth and clean finish.

Zinc rods are used in thermal spraying metal to create durable protective coatings. The zinc is heated until molten and sprayed onto the substrate, forming a strong layer that improves resistance to corrosion and wear. This method not only extends the lifespan of metal components but also provides a cost-effective way to protect surfaces in harsh environments.

Unlike zinc wires or sheets, zinc rods are solid bars.

Higher purity levels, such as our 99.995% virgin zinc, showcase consistent metallurgical properties, making them ideal for critical applications like electroplating and galvanization.

Zinc rods should be stored in dry, well-ventilated areas away from moisture and corrosive chemicals to prevent surface oxidation or damage.

Zinc rods are widely used in industries such as automotive, construction, electrical, marine, and heavy machinery for coating, plating, and corrosion protection.

Yes, our zinc rods are 100% recyclable without loss of quality, making them a sustainable choice for industries focused on eco-friendly solutions.